Inquiry Form

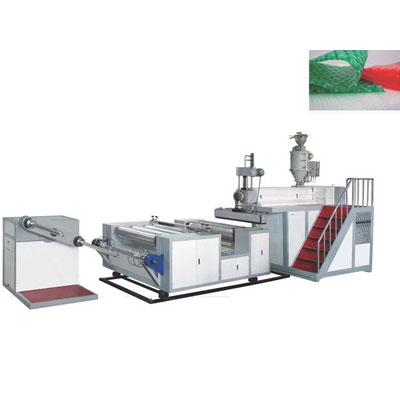

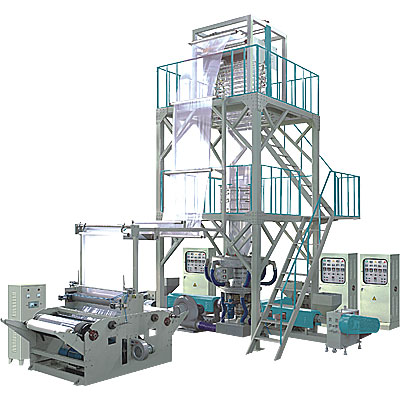

Application of Double-layer Extruding Film Casting Machine JDSJ

This machine set is used for producing LDPE or LLDPE stretch film.

If the machine adopts double screws, the two hoppers should use different type of material, one side of the extruded stretch film is adhesive and the other side is normal. It is widely used for packing architecture and hardware parts etc.

Features of Double-layer Extruding Film Casting Machine JDSJ

1. Screw and cylinder are all made of 38CRMOALA alloy and treated by nitrogen. It has an advantage of corrosion resistance and endurance etc.

2. The cooling device adopts cycle water cooling; provide the best transparent effect of the stretch film.

3. Take-up equipment adopts with friction type rewinding, and equipment with edge correcting device to ensure the quality.

Note: All equipments supplied by our company are not include attached unit(water, air, electricity)

Technical Parameters of Double-layer Extruding Film Casting Machine JDSJ

| Type | JDSJ-50x2 |

| Screw Dia. | φ50mmx2 |

| Length/Dia. of Screw | 30:1(L/D) |

| Product Width | 200-550mm |

| Product Thickness | 0.015-0.03mm |

| Output | 40kg/h |

| Main Motor Power | 7.5kwx2 |

| Heating Power | 30kw |

| Machine Weight | 3.5T |

| Machine Dimension | 5600x2600x1800mm |

| Power Supply | 380/3/4/50(Volt/Ph/Line/Hz) |