Introduction:

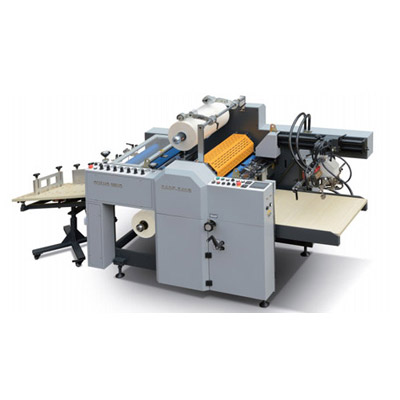

FM-1200 Automatic Waterbased Cold Laminating Machine is designed for cold waterbased glue lamination, speed up to 100m/min, features high automation, high laminating speed, high accuracy, electrical appliance is centralized by programmable system, easy to operate.

Configuration & Functions:

1.Automatic High Speed Feeder: Adopt high speed pneumatic offset feeder, speed up to 100m/min. Pre-stacking system can realize non-stop feeding, obviously improving work efficiency.

2.High Accuracy Lap Control: Servo-controlled lap within ±2mm, synchronizes with feeder, high accuracy front lay and pnuematic side lay regulator ensure accurate and stable position.

3.Automatic Shutdown Protection System: Equipped with photoelectrically controlled automatic shutdown protection devices, in case of paper shortage, paper broken and paper overlap.

4.Immerging Coating System: Adopts immerging coating method, can save glue consumption and easy to control coating amount.

5.Heating Lamps: Equipped with heating lamps, ensure that the machine can work in cold weather.

6.Perforation Knife: Equipped with high accuracy perforation knife, cooperate with our pneumatic differential pull and separating device to cutsheets perfectly.

7.Rewind to Roll: After lamination, the sheets are rewound to roll to dry the glue and prepare for cutting.

8.Anti-curvature Delivery Platform: Especially designed for thin paper, avoid paper curvature.

Parameter:

|

Model |

FM-1200 |

|

Max.Paper Size |

1000X1150mm |

|

Min.Paper Size |

285X350mm |

|

Paper Thickness |

100-500gsm |

|

Film Thickness |

8~25 micron |

|

Max. Speed |

100m/min |

|

Voltge |

380V 50Hz |

|

Total Power |

8KW |

|

Working Power |

3~5KW |

|

Lap Accuracy |

±2mm |

|

Coating Glue Amount |

3~8g/m^2 |

|

Hight of Feeder Pile |

1000mm |

|

Dimension (L*W*H) |

4900×2000×2100 mm |

|

Wood Box Dimension (L*W*H) |

1820×2050×2200 mm(FEEDER) 2000×2050×1900 mm(Laminating part) |

|

Total Weight |

2000 kg |

Machine Photo:

1.Feeder Part

Adopt high speed offset feeder and chain drive non-stop pre-stacking system, can feed sheets up to 100 m/min, smoothly without stop, obviously increase the efficience.

2.Delivery Platform

Equipped with high accuracy front lay and pneumatic side lay regulator, accurate position, anti-curvature device can deliver sheets in high speed without curvature.

3.Control Panel

Equipped with color touch screen, easy and convenient to operate. The operator can view the machine's working status at any time from the touch screen. Temperature controler ensures temperature stable and easy to adjust.

4.Lamination Main Part

Adopts Immerging coating system with rubber coating roller, can coat glue even and save much glue.

Rubber and high accuracy mirror laminating rollers ensure high laminating performance.

5.Heating Lamps

Equipped with heating lamps to ensure glue can work in cold weather.

6.Perforation Knife

Equipped with High accuracy Perforation Knife, assist for cutting process.

7.Electric Parts

Electrical appliance is centralized by programmable system

8.Rewinding Part

After lamination, the sheets are rewound to roll to dry the glue and prepare for cutting.