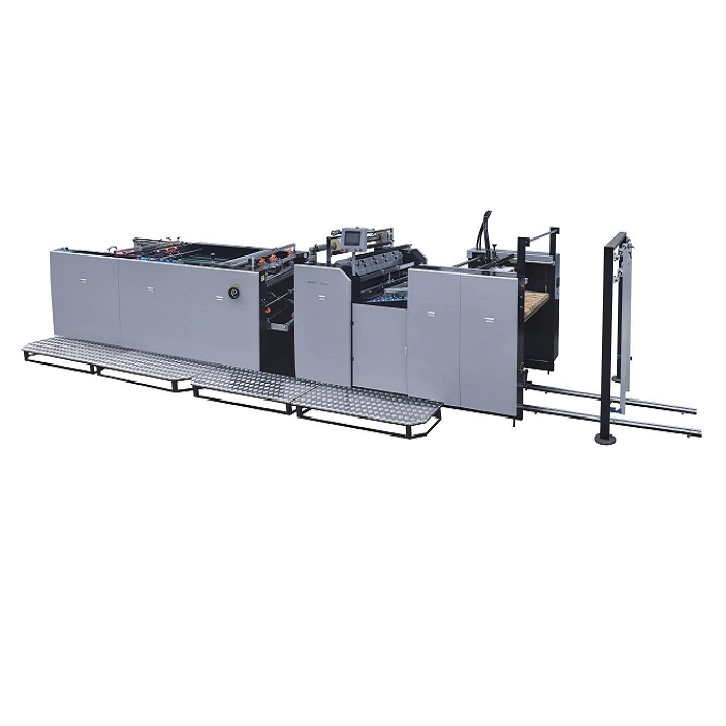

1.Auto Feeder

This machine is equipped with a paper pre-stacker, Servo controlled feeder and a photoelectric sensor to ensure that paper is continuously fed into the machine.

2.Side Lay Regulator

The Servo controller and side lay mechanism guarantees precise paper alignment at all times.

3.Corrugated Delivery

A corrugated delivery system collects paper easily.

4.Electromagnetic Heater

Equipped with advanced electromagnetic heater. Fast pre-heating. Energy saying. Environment protection.

5.Double face laminating

Electromagnetic heating , double face laminating machine.

6.Human Computer Interface

User-friendly interface system with a color touch screen simplifies the operation process. The operator can easily and automatically control paper sizes, overlapping and machine’s speed.

7.Suction Device

Suction device guarantees stability and smooth of paper sending.

8.Fly knife and perforating system

9.Anti-curve Device

This machine is equipped with an anti-curve device, which ensures the paper remain flat and smooth during the lamination process.

10.Automatic stacker

The pneumatic stacker receive the paper, keeping them in order, while rapidly counting every sheet.

11.Film Loader

Saving time of film loading and uploading , improving efficiency.

12.Option:

Chain Cutter System applying BOPP, PET, PVC film.

Technical parameter:

|

Model |

YFMA-1200A |

|

Max Paper Size |

1200x1450mm |

|

Min Paper Size |

350x350mm |

|

PaperThickness |

100-500g/m2 |

|

Laminating Speed |

0-60m/min |

|

Total Power |

40KW |

|

Total Weight |

6000kg |

|

Overall Dimensions |

12000x2200x1900mm |

Video link on youtube : https://youtu.be/rEcUELF_bKA