In the dynamic paper bag manufacturing industry, businesses often have unique production requirements. The question of whether a paper bag making machine can be customized to meet these specific needs is of great significance. The good news is that, in most cases, paper bag making machines can indeed be customized, and this customization offers a range of benefits.

1. Feasibility of Customization

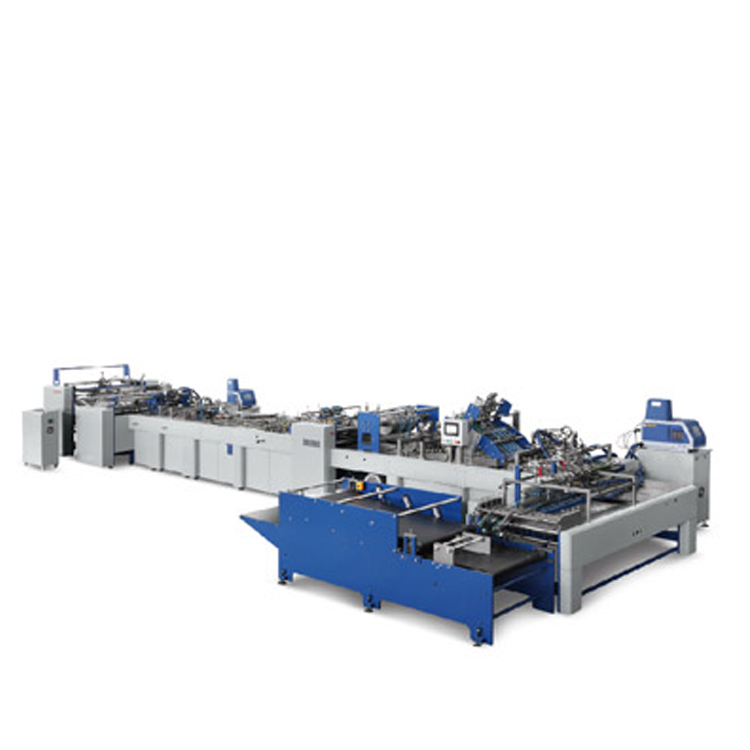

The structure and design of paper bag making machines are flexible to a certain extent. Manufacturers are equipped with the technical expertise and resources to modify existing machine models or develop entirely new ones based on customer requests. With the advancement of modern manufacturing technologies, such as computer - aided design (CAD) and computer - numerical - control (CNC) machining, it has become easier to precisely customize machine components to fit specific production requirements.

2. Aspects of Customization

2.1 Function - specific Customization

Some businesses may require special functions in their paper bag making machines. For example, if a company specializes in producing eco - friendly paper bags with a unique biodegradable coating, the machine can be customized to include a coating - applying mechanism. This mechanism can be integrated into the existing production process, allowing for the seamless application of the coating during the bag - making process. Similarly, for those producing paper bags with complex printing patterns, the machine can be customized to accommodate high - precision printing systems, ensuring that the bags meet the aesthetic and branding requirements.

2.2 Size - related Customization

The size of the paper bags produced is a crucial factor. Different customers may need bags of various dimensions, from small jewelry - sized bags to large grocery - store - sized ones. A customized paper bag making machine can be adjusted to handle different paper widths, lengths, and bag - depth requirements. The cutting and folding mechanisms can be re - engineered to ensure accurate sizing of the bags, regardless of whether they are standard or non - standard sizes.

2.3 Automation - level Customization

The level of automation in a paper bag making machine can also be customized. Small - scale producers with a limited budget or a lower production volume may prefer a semi - automatic machine. This type of machine allows for some manual intervention, such as paper feeding or bag - handling, which can be cost - effective. On the other hand, large - scale manufacturers with high - volume production needs may opt for a fully - automated machine. These machines can be customized to include features like automatic paper roll - changing, continuous bag - discharging, and self - diagnostic systems, which significantly improve production efficiency.

3. Advantages of Customization

Customizing a paper bag making machine offers several advantages. Firstly, it enables businesses to produce paper bags that are tailored to their target market. This can give them a competitive edge, as they can offer unique products that meet the specific needs of their customers. Secondly, a customized machine can improve production efficiency. By eliminating unnecessary functions and optimizing the machine for the specific production process, manufacturers can reduce production time and costs. Finally, customization can enhance the overall quality of the paper bags produced. With precise control over the production process, the likelihood of errors and defects is minimized.

4. Challenges in Customization

However, customization also comes with some challenges. One of the main challenges is the cost. Custom - made machines usually require more investment in terms of research, development, and production. The cost of specialized components and the time spent on engineering the customizations can be significant. Additionally, customization may lead to longer lead times. Since the machine is being built or modified according to specific requirements, it may take longer to deliver compared to off - the - shelf models. Another challenge is the potential for maintenance complexity. Custom - made machines may have unique components and systems, which can make it more difficult to find replacement parts and trained technicians for maintenance and repairs.

In conclusion, while there are challenges, the ability to customize a paper bag making machine according to specific production needs is a valuable option for businesses in the paper bag manufacturing industry. By carefully considering the advantages and challenges, companies can make an informed decision on whether customization is the right choice for their operations.