Paper cup making machine news catalog

Brief introduction of paper cup making machine

paper cup making machine classification

paper cup making machine process

paper cup making machine cam principle

Preparations for the paper cup making machine before starting and during production

Brief introduction of paper cup making machine

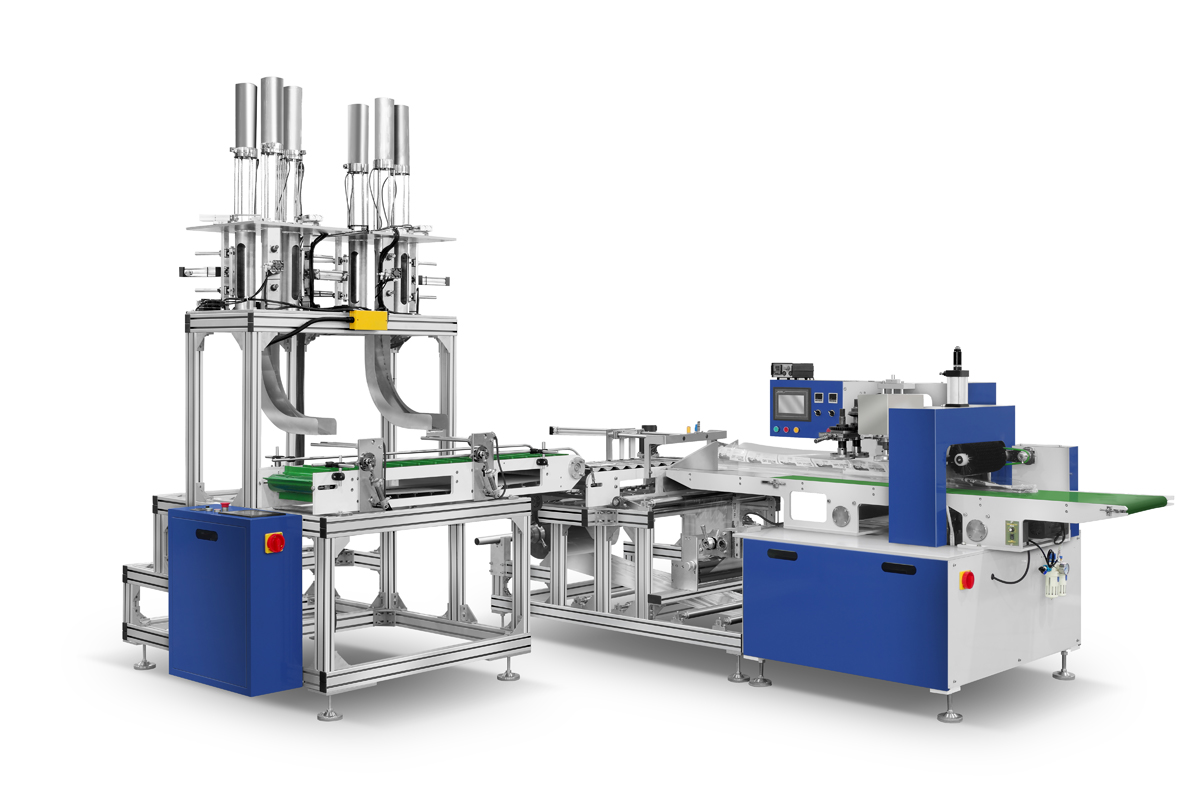

The paper cup is a kind of paper container made by mechanical processing and bonding of base paper made of chemical wood pulp. It has a cup-shaped appearance and can be used for frozen food and hot drinks. The paper cup machine is a machine that automatically processes fan-shaped paper into paper cups. It is safe, hygienic, lightweight, and convenient. It is ideal equipment for hotels, restaurants, restaurants, milk tea shops, and cold drink shops.

paper cup making machine classification

Paper cups are divided into single-sided PE-coated paper cups and double-sided PE-coated paper cups

Single-sided PE-coated paper cups: Paper cups produced with single-sided PE-coated paper are called single-PE paper cups (common market paper cups in China, most of the advertising paper cups are single-sided PE-coated paper cups), and its manifestations are: paper cups filled with water The side with smooth PE coating;

Double-sided PE-coated paper cups: Paper cups produced with double-sided PE-coated paper are called double-sided PE paper cups. The form of expression is: the inside and outside of the paper cup have PE coating

Paper cup size: We use ounces (OZ) as the unit to measure the size of paper cups. For example, 9 oz, 6.5 oz, and 7 oz paper cups, etc. are common in the market.

Oz (OZ): Oz is a unit of weight, here it represents: 1 ounce is equivalent to the weight of 28.34 milliliters of water, which can be expressed like this: 1 ounce (OZ) = 28.34 milliliters (ml) = 28.34 grams (g)

Paper cups: In China, we call 3--18 ounces (OZ) cups paper cups. Regular paper cups can be produced on our LBZ-LI or LBZ-L paper cup-forming machines.

paper cup making machine process

Bonding process: The equipment has a heating station to heat the PE film on the surface of the PE-coated paper and compact it through the side and bowl bottom pressing mechanism. After cooling, the firm bonding effect can be achieved.

The forming process of the paper cup machine is not complicated. The paper cup is mainly composed of two parts: the cup wall and the cup bottom. Therefore, the forming process of the paper cup machine is to process the cup bottom and the cup wall separately, and then firmly integrate them.

The paper cups processed by the paper cup machine are mainly coated paper. The cup wallpaper can be printed with exquisite patterns in advance and then processed into a fan shape, while the cup bottom paper can be rolled paper. The forming process of the paper cup machine is as follows:

First of all, the paper cup machine will automatically process the printed fan-shaped paper into a paper cup tube, and then glue the paper cup wall through thermoforming, while the paper cup bottom uses roll paper, and the paper cup machine will automatically feed the paper, blanking.

Then, the paper cup machine will seal the bottom of the cup and the cup wall, and then there will be hot air blowing and bonding. The next step is the knurling step of the paper cup machine, which is to roll a layer of impressions through mechanical movement when the bottom of the paper cup is glued. The last is the curling step of the paper cup machine, which is to shape the curling of the mouth of the paper cup.

The work content of the paper cup machine is to start from automatic paper feeding, and then produces finished paper cups through continuous processes such as bottom punching, sealing, heating, bottom turning, knurling, edge curling, and cup unloading.

Paper cup machine cam principle

The production and manufacture of paper cups is an iterative process, and more paper cups are produced by repeating the same actions.

The continuous repetitive action of the paper cup machine is accomplished through the cam mechanism in the paper cup machine. The cam in the cam mechanism of the paper cup machine performs rotary motion, which pushes the follower of the paper cup machine to reciprocate according to certain requirements.

The cam structure of the paper cup machine can make the follower of the paper cup machine obtain a more complex movement law, thereby realizing the cycling effect of cardboard production and meeting the demand for producing more cardboard products.

The cam mechanism has the characteristics of a simple and compact structure and design and can complete various complex motion requirements, which makes it not only excellent for use in paper cup machines but also plays an important role in other equipment.

Preparations for the paper cup machine before starting and during production

(1) After the preparatory work is completed, when the motor is about to be started, it is necessary to shout "start-up" and the motor can only be started when there is no response. (This is to prevent the operator from seeing and causing unnecessary safety accidents when the mechanic is repairing on the opposite side or behind the machine).

(2) Carefully observe the machine's operating conditions, take a cup to check the bonding effect of the paper cup, preheat, main heat, and whether there is yellowing at the knurl or damage to the paper cup.

(3) Check the bonding effect of the bonding place, whether there is any indirect defect, the bonding firmness of the bottom of the cup, and whether the bonding is suitable for tearing and fluffing. prevail.

(4) During normal operation, if you find or feel that there is something abnormal about the machine, you should lift the cup body away first, and then stop the machine for inspection after the last cup has passed the knurling.

(5) When restarting the machine after an accidental shut down for a long period of time, take out the fourth and fifth disks and check whether the knurled parts are bonded.

(6) The operator of the paper cup machine pays attention to the shape of the cup mouth, cup body, and cup bottom at any time during normal production, and checks the adhesion, size, and appearance of the cups from time to time or checks one by one.

(7) When the staff concentrates on the operation, if there is any abnormal sound or the bottom of the cup is not well-formed, they should stop the machine immediately for inspection to prevent greater losses.

(8) The operator must be serious and responsible in the production process and test the cups produced by himself with boiling water once an hour, 8 cups each time.

(9) Before the operator seals the carton, the number of small packages should be randomly checked. After the random inspection is correct, cut out the product certificate or product pattern and paste it on the upper right corner of the left side of the carton, and fill in the job number and production date in the box. , and finally sealed and stacked neatly in the designated location.